How can we use the technological tools we were exposed to in the course to produce a facade that is economical in material, with soft and hard qualities, which can be assembled and disassembled easily?

Digital production methods: 2D laser cutting, 3D printing, CNC

CNC

LASER CUT

3D PRINTER

work process:

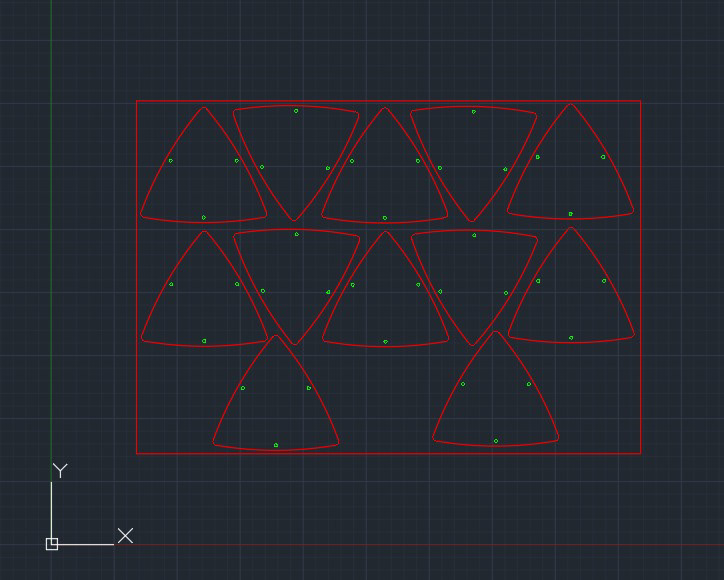

Laser cutting - we cut the fabric with the 2D laser machine. We prepared a plan of the module in AutoCAD. The machine ran for one hour.

3D printing - we designed the fasteners in Rhino and used a home 3D printer. Printing the pieces for the 1meter x 1meter facade took a whole day.

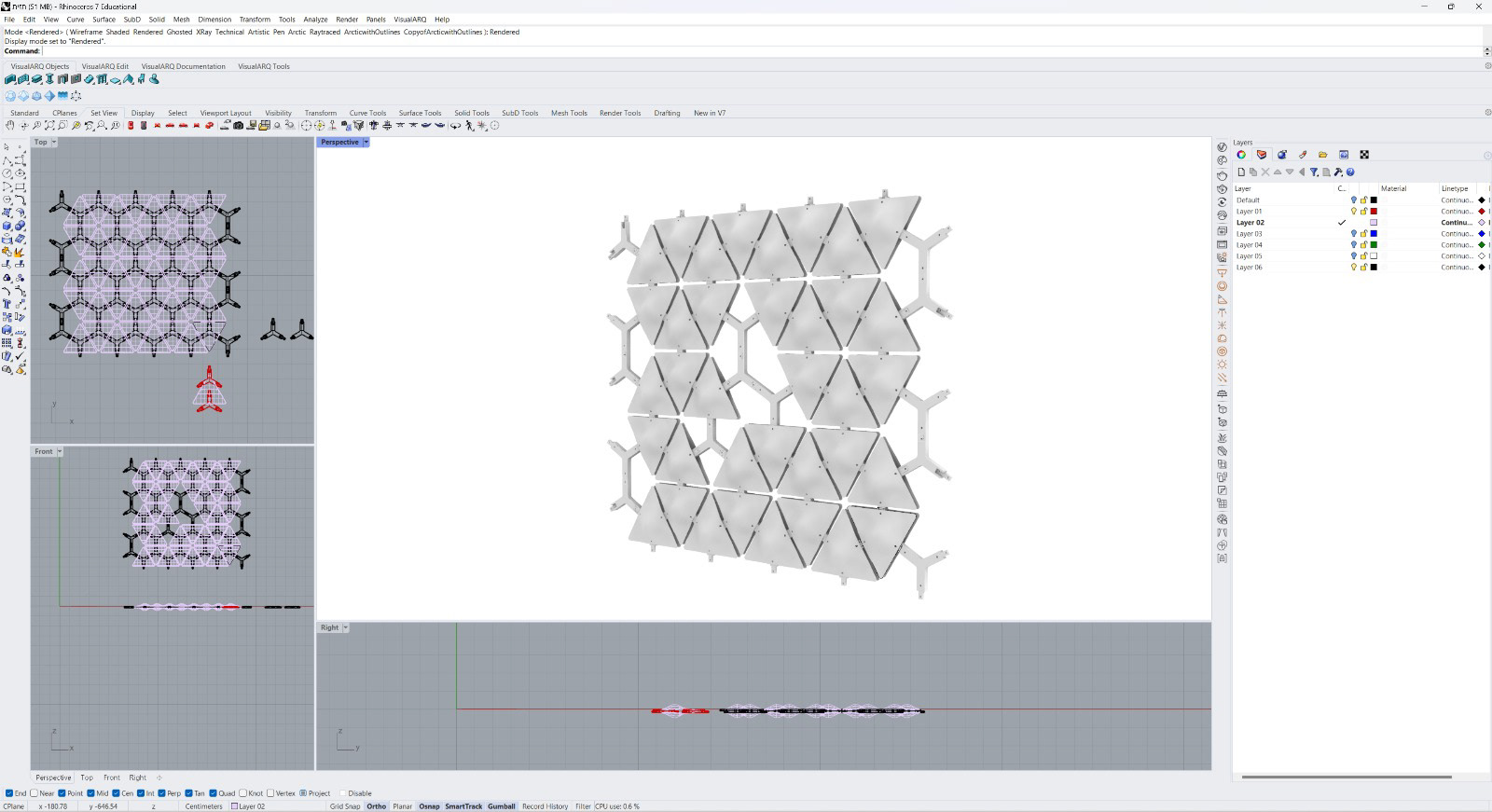

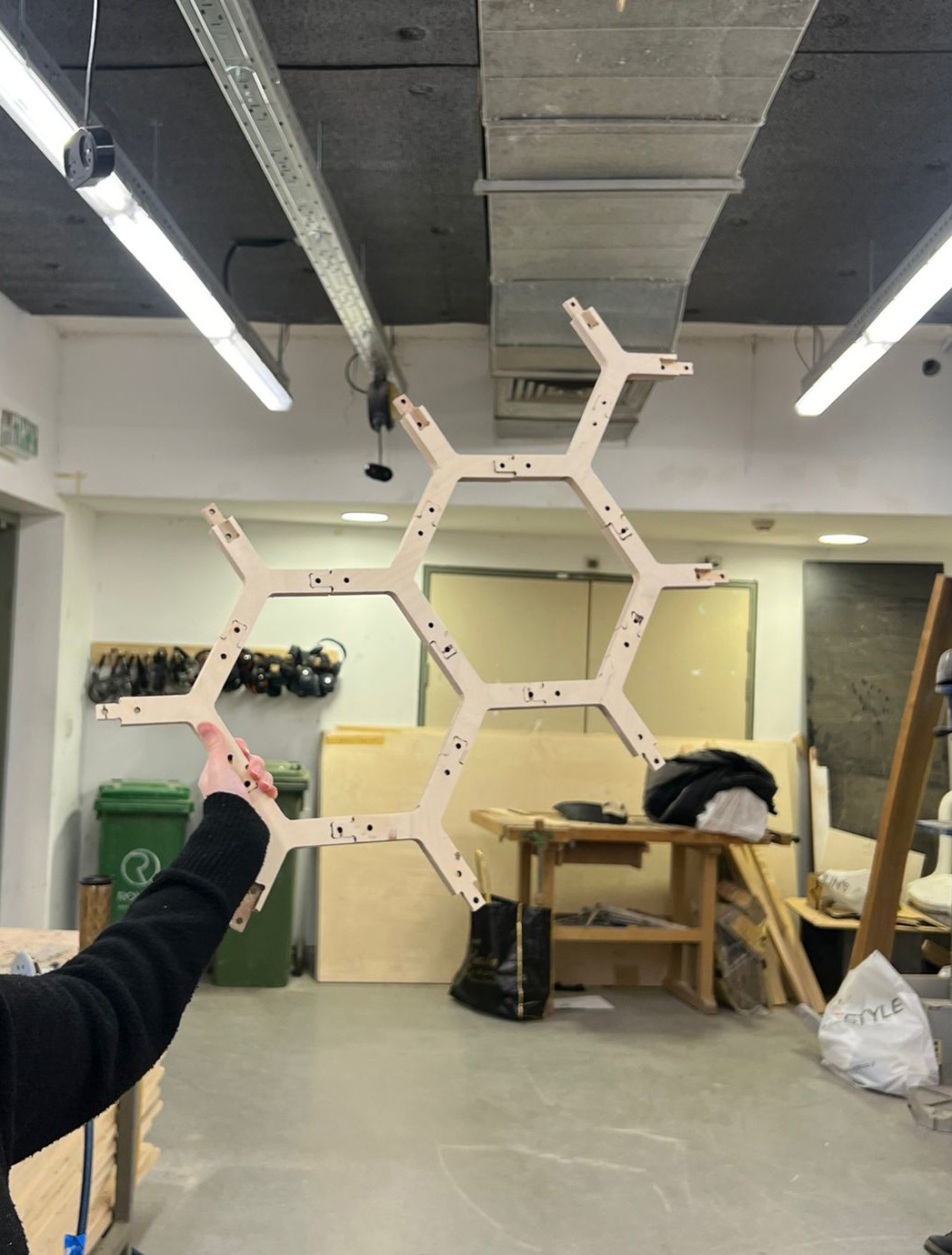

CNC 2D - we cut the wooden construction with the machine, designed the module in Rhino and adapted the module to the size of the mill. Through a first attempt we learned the offset required for the joint so that the construction would connect easily. The machine worked for four hours.

FABRIC UNITS FOR LASER CUT

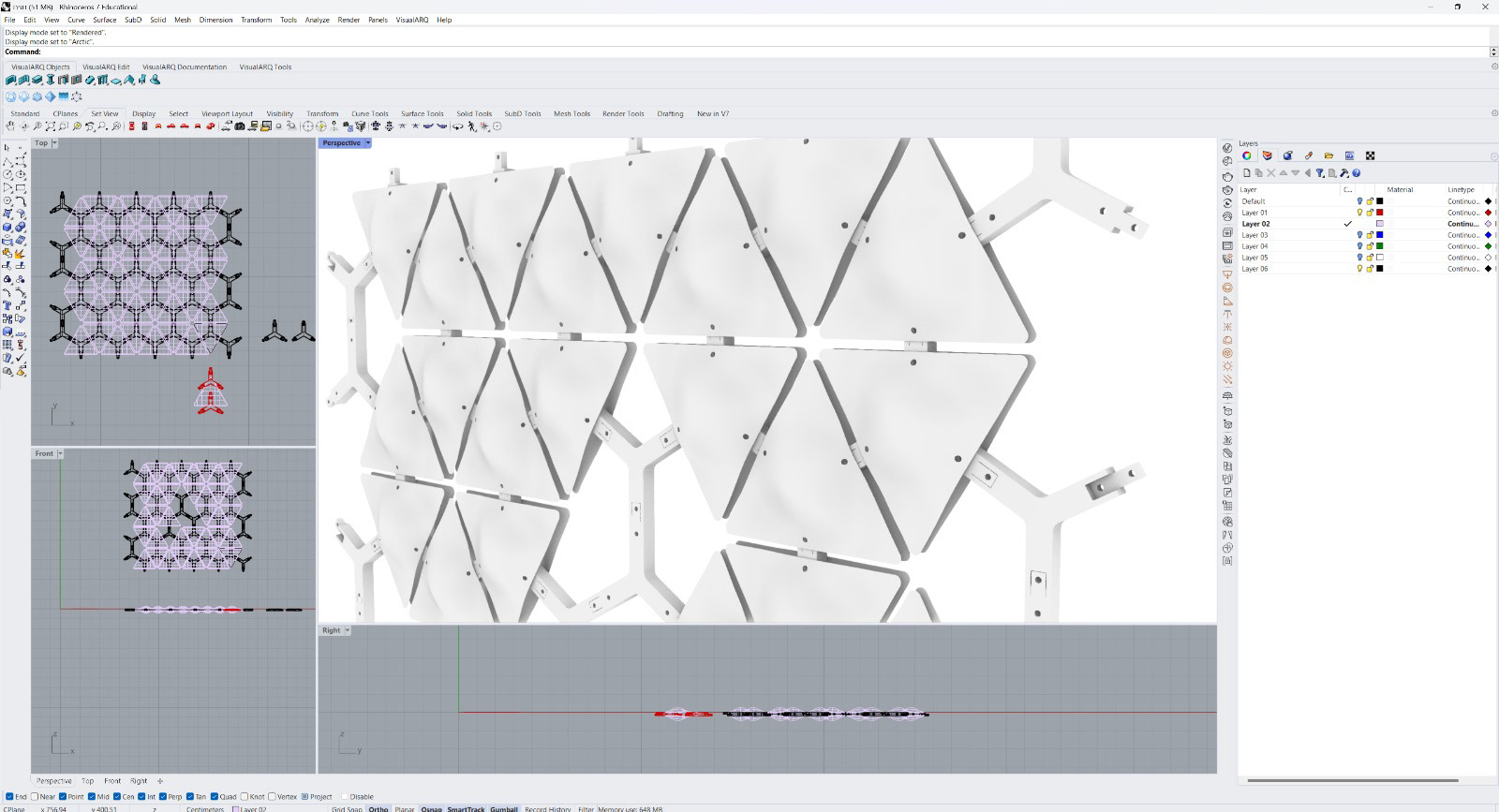

PLANNING | RHINO

PLANNING | RHINO

3D PRINTING PROCESS

3D PRINTING PROCESS

3d printed screws

CNC PROCESS

Perfectionism...

DEMO TEST

We believe that by using technological tools we can work efficiently and economically. We made sure to create modules with minimum waste of material, and chose to use fabric because of leftover geotechnical fabric that can be found on construction sites.

In addition, the design of the construction was based on a repeating module, which can function as both a male and a female connector, by simply turning it over. We wanted to produce a module that breaks down into packageable pieces, neither too small nor too big. In addition, not only was important for us to produce a uniform, efficient module but also with the potential to be customized- the user can alter the product to different dimensions.

Fabric can also be adjusted according to the user's need, by easily controlling the level of its density when constructing. The combination of the fabric and the construction also adds an acoustic quality to the element. Fabric of various types can be used, with variable thickness and acoustic insulation qualities.

The joint is easy to use. As the facade expands, the number of fasteners required increases – therefore we chose a noticeable color to reduce the chances of losing pieces.

TEAM WORK

THE FACADE

THE FACADE

ZOOM IN : THE 3 COMPONENTS

Wooden construction